I thought I would try some investment casting using pewter. Pewter is nice because it has such a low melting point that is is very easy and fast to work with. I am using plaster of Paris for the investment... this is not recommended ...if there is moisture still in the investment, it could cause an explosion when you pour...especially if you are using hotter metals. At the high temperatures you would need to fully burn out the water, POP would break down I have been told. I tried a couple of different waxes and mixtures to do these. My basic wax was made using parafin,candle wax, and toilet bowl ring wax. The toilet bowl ring is a very soft wax. I added some plastic bags (shopping bags) too when I melted the wax. I heard you can do that somewhere to add strength to the wax. For some rings, I tried a straight glue gun glue. This was very easy to work with but it didn't burn out well for me. Here are some of the rings. The one on the left is a rough blank. I used my glue gun to make a thin bead of wax in the middle strand...and straight glue on the one to the right. Then I braided the strands.

The investment was half plaster of paris mixed with half sand. I poured the mix into the flasks and then put them into my vacuum chamber. Remember...I do not recommend you do this...use real investment. Plaster of Paris can be dangerous because of the way it holds onto water! I thought I had taken other pictures of the investment burning out in my oven...but I can't find them. What I did was to burn out the wax in a toaster oven. I put the temperature to 200 for a few hours to burn out the wax, then turned it up more every few hours until it was at about 550 degrees F. I figured that if the plaster of Paris was burned out to that temperature, that would be enough because the pewter is poured at around 525 degrees.

To pour, I put the flasks onto my vacuum pad, turn on the vacuum for about 10 seconds and then pour. Hopefully this will be more clear when you watch the video. Here are some pictures of my vacuum set up. I have a friend who does HVAC and when I asked him if he had any old compressors that I could make into a vacuum pump, he told me he had a little vacuum pump that he wasn't using because it was too small for him...so he gave it to me! It was a happy day!

vacuum chamber

Plexiglass

Plexi Upside down

Other Plexi with hole and weather stripping placed on top of 1st Plexi

Silicon Pad that flask gets put on for seal

freshly poured

Past E-zines (Click on picture to visit page)

CNC Router Pewter Bell Video Part one..You can click on the next two from there

Swedish Horse Lost Foam Cast in Brass

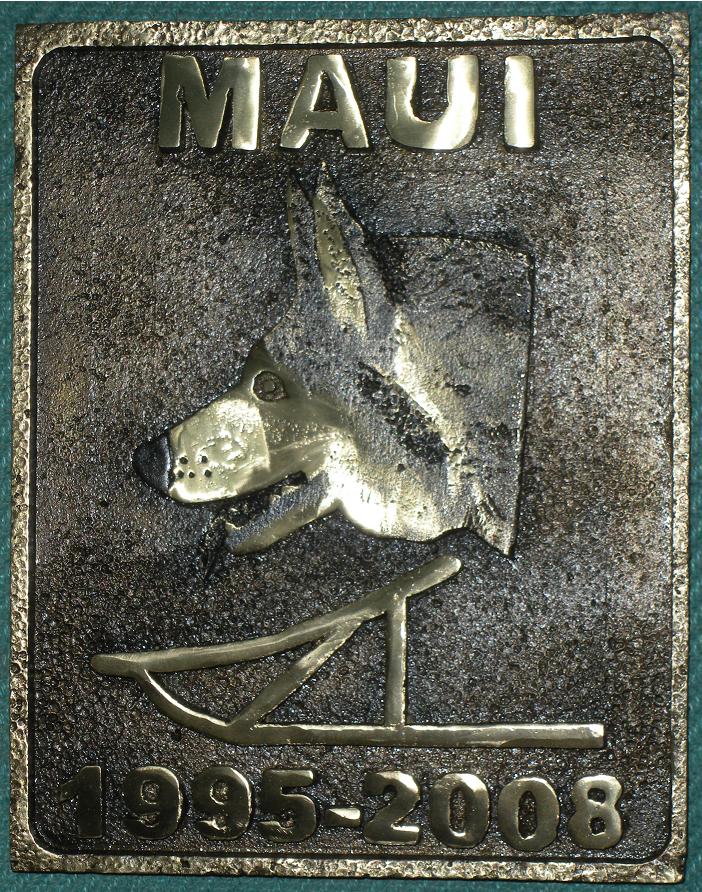

Dog Plaque Lost Foam Cast in Brass